Case Study: 3 Stannah goods lifts support growing CLEAN Yeovil laundry

A trio of Stannah Goodsmaster CD goods-only lifts has been installed in the Yeovil branch of CLEAN Linen and Workwear.

Installed over three years, each lift reflects and supports the depot’s ongoing development by lightening the growing workload.

About CLEAN Yeovil

Part of CLEAN Linen Services, CLEAN Yeovil is a vital link in one of the UK’s leading independent laundry companies, an organisation that delivers linen and workwear rental services to leading brands such as Harbour Hotels, Honda and Premier Inn.

PROJECT OVERVIEW

Client: CLEAN Linen Services Limited

Total upgrade project cost: £7 million

Stannah Goodsmaster CDs:

1 x 1500kg—installed in 2019

1 x 1000kg—installed in 2018

1 x 500kg—installed in 2017

Supplied in a structure-supported frame, each lift was quick and easy to install in a matter of days. The Stannah installation team flexed around the premises’ operation with minimum disruption to everyone involved.

"The first lift was installed to service our first-floor storage / chemical room back in 2017. The second lift was installed 2018 to service the mezzanine floor. The third lift was installed in 2019 to run parallel with the mezzanine floor lift installed in 2018."

—Daniel Stalley, Engineering Manager, CLEAN Yeovil

RESULT

An efficient, responsive laundry depot—fit for purpose and responding to the industry’s growing laundry-load.

Why specify a third Goodsmaster CD?

“Since opening in July 2011 the plant has grown significantly, from delivering 250,000 pieces of linen per week to our customers to now 800,000 pieces per week.

“We have seen significant investment over the years to accommodate this growth. One addition to the plant was a mezzanine floor, installed in 2018 as floor space was becoming very tight.

“The mezzanine is used to hold the cages of soiled linen prior to sorting and washing. We needed a reliable lift to transport circa 600 cages per day up and down. The latest goods lift was one of several choices offered to us by the company who installed the mezzanine floor – Rose Engineering. We were happy to opt for the Stannah Goodmaster CD 1500kg as its two predecessors perform to our complete satisfaction.

“We are happy with the construction, performance and durability of the lifts and the service from Stannah. There was a small hitch with the first installation, but this was rectified quickly. I would be quite happy to purchase another lift from Stannah if required in the future.”

—Geoff Milverton, Site Director, CLEAN Yeovil

From the specifier, Joe Baker, Estimator at Rose Engineering

“We worked closely with our client, CLEAN Yeovil, to deliver a goods lift to match their exact requirements—a sturdy lift that would transport heavy, laundry-laden roll cages between two floors.

“From the choices we offered they chose Stannah as they have a previous contract with this company, so they knew exactly what they would be getting and that it would deliver exactly what was required of it—including the after-sales service.”

PROJECT DEEPVIEW

About the CLEAN Yeovil Goodsmaster CD goods lifts

Capacities: 500kg, 1000kg and 1500kg

Load: Roll cage or pallet

Speed: 0.15 m/s VVVF

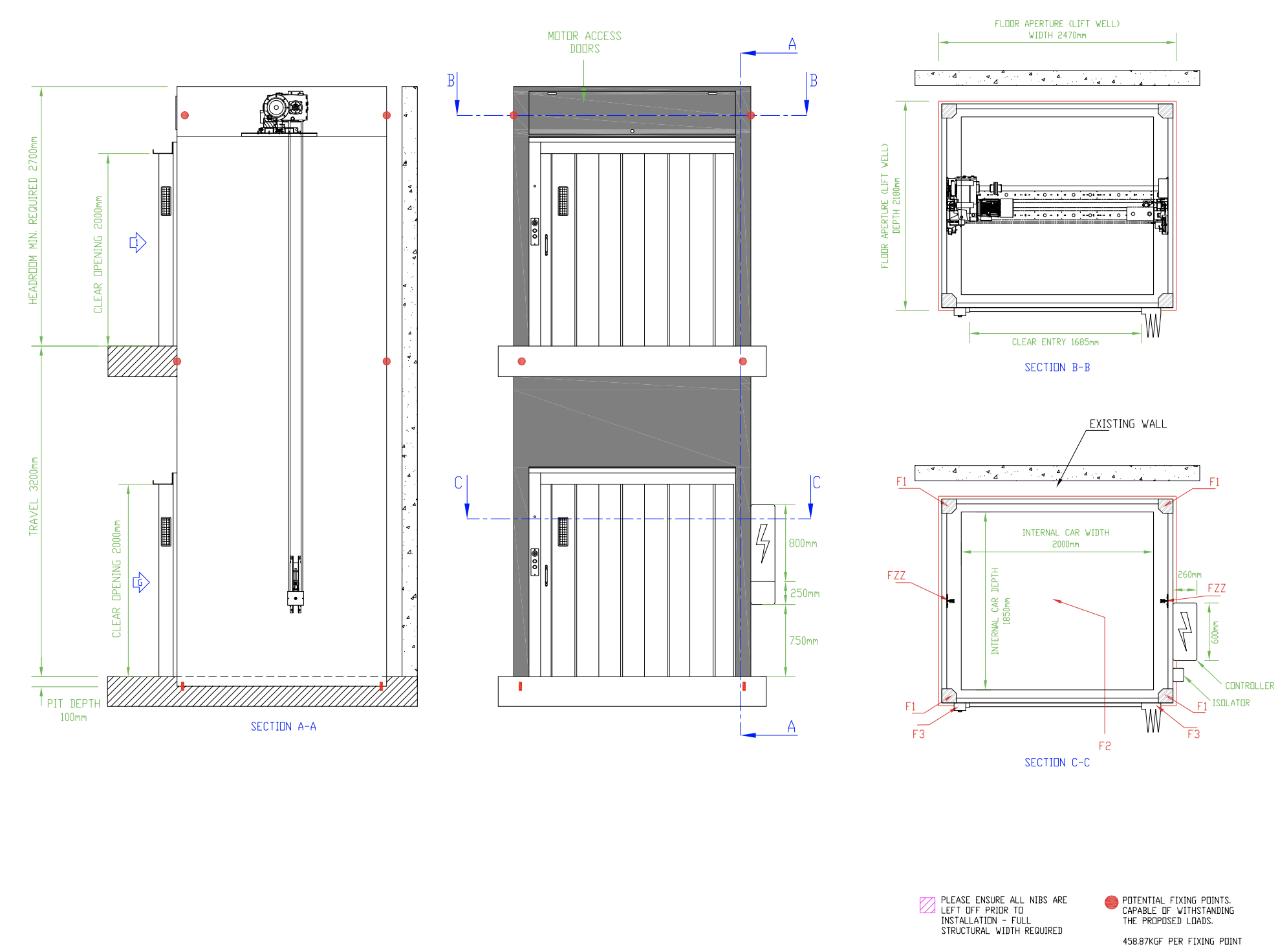

Travel: 3200mm

Serving: Floor level

Levels served: Ground and 1st-floor storage (1) or mezzanine (2)

Mounting: Structure-supported

Shaft details: No supporting walls required. Support is needed at each floor level, at the top of the lift and at pit/base level for fixings.

Finish: Lift enclosure in non-fire rated black epoxy RAL 9005 sheet steel.

Floor aperture: 2470mm wide x 2180mm deep

Headroom: 2750mm minimum clear required

Pit depth: 100mm (no ramp needed)

Power supply: 415V— three-phase—50 HZ

Drive: Chain\Motor: Electric geared/braked motor unit located overhead with two roller chains directly attached.

Guides: two off tee section

Controller: Lockable relay cabinet, 600mm wide x 260mm deep x 1060 mm high

Control system: Fully automatic push button with stainless steel faceplate at each landing entrance. No controls in the car itself.

Indicators: ‘Lift here’ and ‘Lift occupied’.

Lift car

Entrance positions: one per floor on fronts.

Entrance size: 1685mm wide x 2000 high.

Car size: 2000mm wide x 1850mm deep x 2000mm high

Design: Steel-framed car finished in grey epoxy (RAL 7032) with aluminium chequerplate to floor and galvanized ceiling.

Lighting: Fluorescent tube lighting.

Car entrance protection: Collapsible gate

Landing doors: Concertina landing gates incorporating lift arrival buzzers, locks and safety contacts; galvanised finish with primed surround.

Goodsmaster CD 1500kg—general characteristics

WHY CHOOSE A GOODSMASTER?

Worker protection

Large, robust and efficient, the Goodsmasters move heavy goods whilst removing the risk of personal injury that comes from manual handling.

Flexible operator

The Goodsmaster CD is available in a range of car and shaft sizes and has minimal headroom and pit requirements. This makes it the ideal choice when it comes to moving heavy loads in tight spaces, between floors or to elevated areas such as mezzanine levels.

Modular design

Supplied in a swiftly erected, self-contained steel frame the Goodsmaster does not require a purpose-built lift shaft. This saves time, money and mess as there is little need for builder’s work.

Safe to use

The goods lifts have many features to ensure their safe use, during operation and maintenance. These comprise:

• Instantaneous safety gear fitted to the lift car, actuated by an overspeed governor

• Slack chain switches

• Load weighing device

• Retiring cams on lift car to provide pre-locking of landing entrance doors

• Journey timer to prevent damage to motor if lift car becomes jammed during travel

• Enclosed lift car roof to prevent unauthorised persons climbing onto the top of the lift car

A COMPREHENSIVE PACKAGE

Standards compliant

The Goodsmasters comply with the Essential Health and Safety Requirements (EHSRs) of the Machinery Directive 2006/42/EC.

Supporting sustainability

Designed and manufactured to be energy efficient and cost-effective to run.

Warranty

As with all Stannah lift products the Goodsmasters were supplied with a 12-month warranty as standard.

Maintenance

All Stannah installations and refurbishments are covered by a maintenance contract. In this case, all three Goodsmaster CD goods lifts are covered by four service visits each a year by the South West England and South Wales branch of Stannah Lift Services.

Stannah offers service, repair, modernisation and refurbishment of all types of lifts, stairlifts, escalators and moving walkways—not only those from the Stannah product range but also other lift manufacturers’ equipment.

Stannah also offers a bespoke lifts service, custom building lifts to meet customers’ specific requirements.

Backed by over 150 years’ experience and expertise

Stannah is a UK market leader in the design, supply, installation, refurbishment and maintenance of a comprehensive range of passenger, service and platform lifts, escalators and moving walkways.

This is the second CLEAN Linen depot to specify Stannah goods lifts—check out the Goodsmaster CD installation in their Slough super laundry